Post-Tensioning Process at Imperial Towers – Podium Level

Masters Management Consultants provided Project Management & Cost Consultancy services for “The Imperial”, a flagship residential complex - 253 metre high, 60 storey towers with the finest of amenities, at the heart of the city of Mumbai. Completed and handed over in 2009, these are the tallest towers in India as on date. The towers are built with state-of-the-art technology and finishes and using international standards of construction. The towers include a podium of 9-storey height which houses car parking, a luxury spa, clubhouse and recreational facilities and a triple-height entrance lobby.

The following photo-essay compiled by Mr. Bivash Bag & Mr. Kamlesh D. Vaidya of Masters’ construction management team, gives a brief insight to the process of casting a post tensioning slab, which was followed for all podium levels of The Imperial.

Materials Required For PT Slab

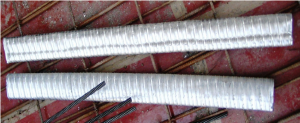

- GI Ducts

- HT Strands

- Chairs of various sizes to maintain Tendon Profile

- Grouting Pipe

- Jack Stressing Machine

Illustration 1: GI DUCTS

Illustration 2: HT STRANDS

Illustration 3: CHAIRS OF VARIOUS SIZES TO MAINTAIN TENDON PROFILE

Illustration 4: GROUTING PIPE

Illustration 5: JACK STRESSING MACHINE

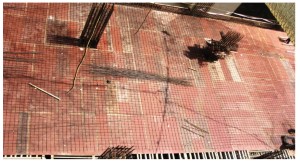

Illustration 6: Completion of Bottom Shuttering

Illustration 7: Completion of Bottom Reinforcement

Illustration 8: GI Duct Laying

Illustration 9: Threading of HT Strands into Ducts

Salient Features

• Ultimate Load Of One Strand = 186KN

• Applied Load (Design load) = 75% of Ultimate Load

• Stressing Pressure = 39.11MPa

• Stressing of strands can be done after achieving 75% strength of concrete.

Executed By

• Project Management – Masters Management Consultants (India) Pvt. Ltd.

• PT Contractor - Utracon

• General Contractor – Shapoorj Pallonji & Company Limited