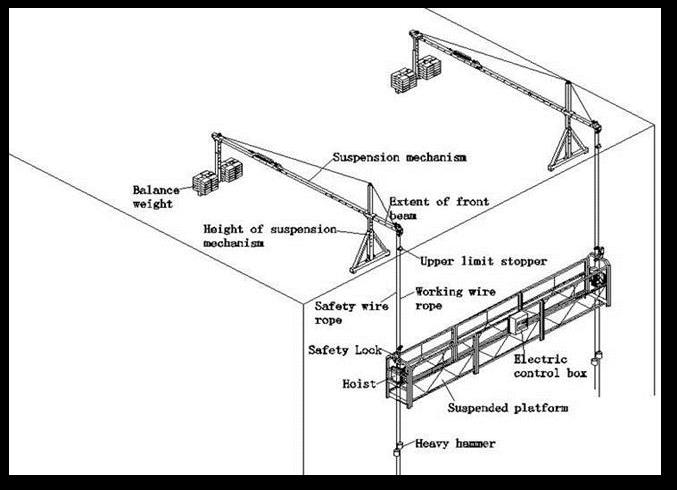

Rope Suspended Platform

In present scenario of construction industry all are fast track projects and time is a chief priority. To survive with the priority, getting skill workmen is very difficult. Hence industry is absolutely depended on new technologies. Rope Suspended platform (RSP) is one among the technology used large wide by contractors resulting reduction in time and cost of construction.

The suspended Platform is high-efficiency modern overhead operation equipment capable of replacing a traditional scaffold and being reused. Generally, the suspended scaffolding can be divided into two kinds: manual and electric. It is widely applied to the outer wall construction, curtain wall installation and outer wall cleaning and maintenance in high rise.

Rope Suspended Platform (RSP) –Major Components:

For every technology some advantages and dis-advantages will be there, even suspended platform is having dis-advantages like toppling; Person falling from height and collapse of platform are more due to unsafe operating and erection of suspended platforms. Based on the study some Standard Operating Procedure for Rope Suspended Platforms are described under.

LIST OF SAFETY GADGETS / SYSTEMS

1. Safety Device:

If the primary rope breaks, the safety lock gets activated and arrests RSP operation through secondary rope within 100 MM.

2. Centrifugal Speed Limiter:

If RSP travelling (Up or Down) speed increased beyond the rated speed, this devices gets activated and stops RSP operation. This device generally activates during free fall  and brake failure conditions.

and brake failure conditions.

3. Electromagnetic Brake with manual release: Hoist motor is provided with electromagnetic brake as primary holding device.

Hoist motor is provided with electromagnetic brake as primary holding device.

Manual release mechanism shall help the cradle to be lowered to the ground level in case of power failure.

4. Over Hoist / Top Limit Switch:

•Function of over hoist limit switch is to prevent the over run of the cradle and hitting the suspension mechanism.

•When the limit switch level touches upper end, power supply to electrical motor gets stopped.

5. Anti-Tilting Cut off:

•This is a protection system to ensure uniform loading across the platform. If the load is concentrated on one side, the platform will get tilted resulting in unsafe condition.

•This device gets actuated once the platform angle is tilted more than 4 Degrees and cuts off the power supply.

6. Anti-Sway Restriction: This mechanism avoids the swaying of RSP in the horizontal plane.

This mechanism avoids the swaying of RSP in the horizontal plane.

A separate wire rope (Laid from building top to ground) will pass through the sway arrestor roller fitted on the platform. This will thrust the platform to remain in the horizontal plane without swaying action. The same shall be used as Fall Arrestor or separately provided as needed.

7. Locking arrangement for upper counter weights:

All the counter weights must be firmly placed on level ground and locked with lock & key arrangement to avoid un-authorized removal of counter weights.

8. Hammer weight for wire rope locking:

Operating wire rope must be firmly anchored at the ground level using hammer weight arrangements.

9. Panel board Lock & key:

•RSP Electrical panel must be locked with lock & key arrangements to avoid unauthorized operation.

•The keys to be handed over to authorized operators by identified RSP In-charge

Back