Construction of Jack-up Floor Slab at Blue Frog by Bivash Bag

The Blue Frog at Lower Parel, Mumbai was conceived to promote international/ world music in a live performance space. The live performances are played out in the intimate environs of a hip, lounge bar and restaurant and can be recorded live in the state of the art studio located adjacent to it.

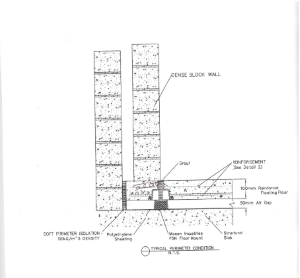

Bearing in mind that a recording studio must have stringent measures for noise and vibration control, one of the requirements stipulated by the acoustic engineers based in the UK was to physically and acoustically segregate not only the walls and ceiling of the studio from the building in which it is encased but also the floor as well. This was achieved by casting a new floor on the existing floor slab and then raising this off the original floor by a series of jacks (very similar to how one jacks up a car to replace a flat tyre).

The process, which was carried out under the direct supervision and involvement of Masters is documented in the photographs below:

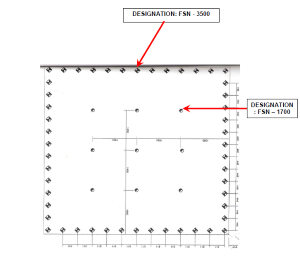

FSN FLOOR PLAN

FSN - 3500

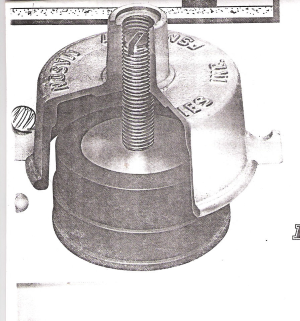

JACK ( FSN – 3500 )

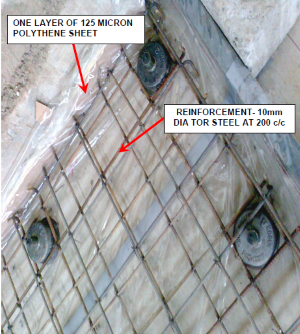

JACKS ARE INSERTED IN THE REINFORCEMENT OF SLAB

( BEFORE CASTING )

STEP - 1

JACKS ARE INSERTED IN THE REINFORCEMENT OF SLAB

( BEFORE CASTING )

AFTER CONCRETING REMOVING OF RUBBER PLUG

SLAB AFTER CASTING

STEP - II

CONCRETING OF THE SLAB IS DONE. (CONCRETE USED IS M35)

STEP – III

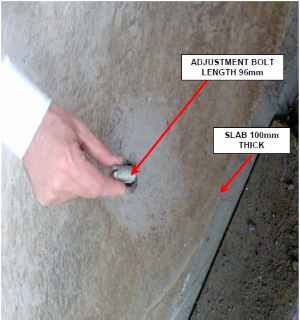

NUMBER OF BOLTS ARE INSERTED IN ORDER TO LIFT IT UP THE SLAB

WITH THE HELP OF ROTATOR.

ROTATOR

STEP - IV

ROTATOR IS USED,TO LIFT UP THE SLAB. ONE ROTATION CAN LIFT THE

SLAB UPTO 3.2mm. 14 ROTATIONS ARE REQUIRED TO LIFT UP THE

SLAB BY 45mm.

AFTER JACK UP